Typical crops they harvest include loose leaf salad plants and low growing herbs such as Thyme, Rocket, Arugula, Baby Spinach, Baby Greens, Cress, Endive, Mache, Mizuna, Mesculin, Romaine, Spinach, Tatsoi, Baby Beet, Mache, Chicory, Micro Greens and others.

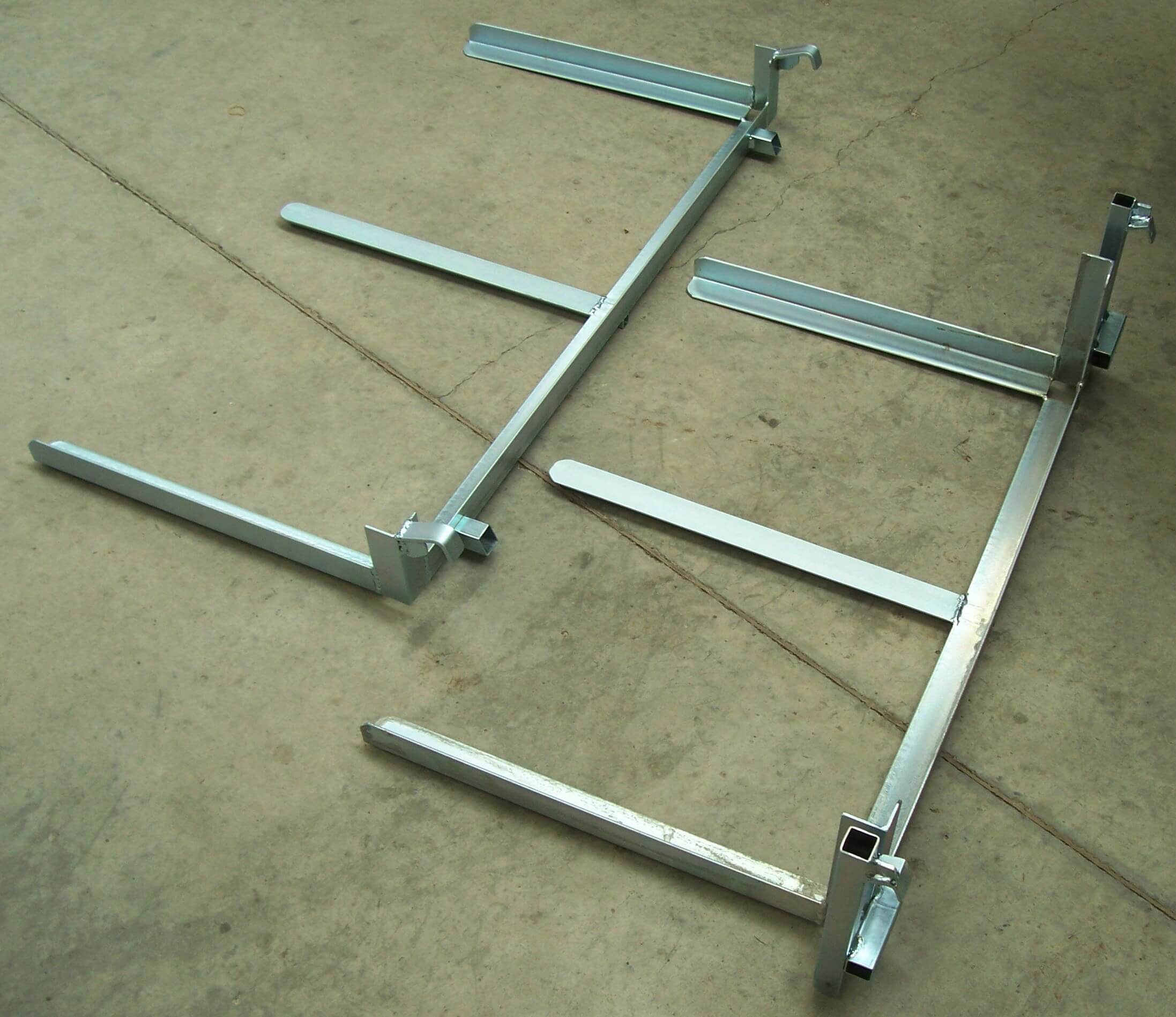

A full width roller behind the cutter bar sets the cut height. As the Harvester is light weight the roller does not damage the plants allowing them to regrow and subsequent harvests made. All HT-Shaver harvesters have a front mounted safety bar which stops the engine if activated. The harvester frames are all zinc plated for durability.

- Description

- Features

- Specification

- Options

- Videos

- Documents

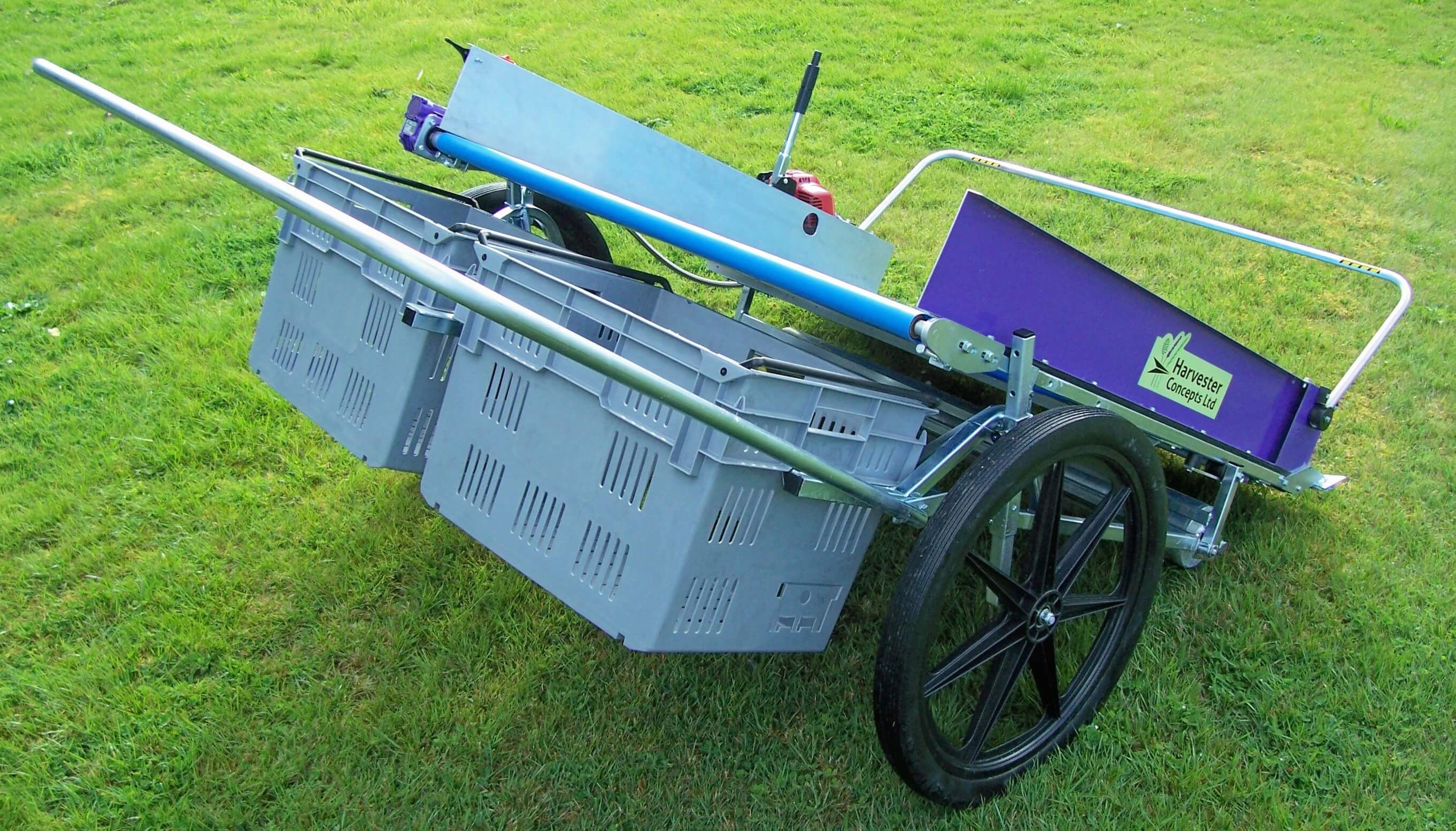

The HT – Salad harvester has motorized cutter bar and also has a in-built blower to blow the cuttings up a chute and into vege bins. It is light weight. Due to the frame layout it does not have enough clearance to travel over uncut crop so must be carried over these areas.

Typical crops the HT-Salad can harvest including loose leaf salad plants and low growing herbs such as thyme, Rocket, Arugula, Baby Spinach, Baby Greens, Cress, Endive, Mache, Mizuna, Mesculin, Romaine, Spinach, Tatsoi, Baby Beet, Mache, Chicory, Micro Greens and others.

- Double reciprocating blades cut the crop cleanly

- Blows the cuttings directly into the bins minimizing handling and damage

- Adjustable cutting height from ground level up to 125 mm in nine steps, easy single lever adjustment

- Single Operator use, can even be used in muddy fields

- Easy bin changes, takes two standard recrate 75 vege bins

- Lightweight

- Stowage for travel wheels, with wheels only fitted when long distance travel is required

- Wheels have quick release feature for allowing compact storage or easy transporting in a vehicle

- Versatile handlebars can be mounted on the front or back of the harvester

- Easy clean design, with chute cover and deflector easily removed, plus construction and materials suitable for quick hose wash-down

- Frame is fully zinc plated for low maintenance

- Standard cutting width is approximately 1200 mm

- Cutting height (above ground): adjustable 0 mm to 125 mm in five steps

- Cutting width: 1200 mm

- Wheel track: approx.. 1400 mm

- Wheel drive: none

- Belt speed: n/a

- Weight, dry: 49 kg

- Collecting bin / bag: two recrate 75 bins

- Engine: Husqvarna Zenoah G23LH-EZ (used to be Komatsu Zenoah) 22.5cc air cooled 2-stroke gasoline engine

We can custom manufacture, so please ask us about your special requirements.

You can download the following documents:

- Description

- Features

- Specification

- Options

- Videos

- Maintenance and Servicing

- Documents

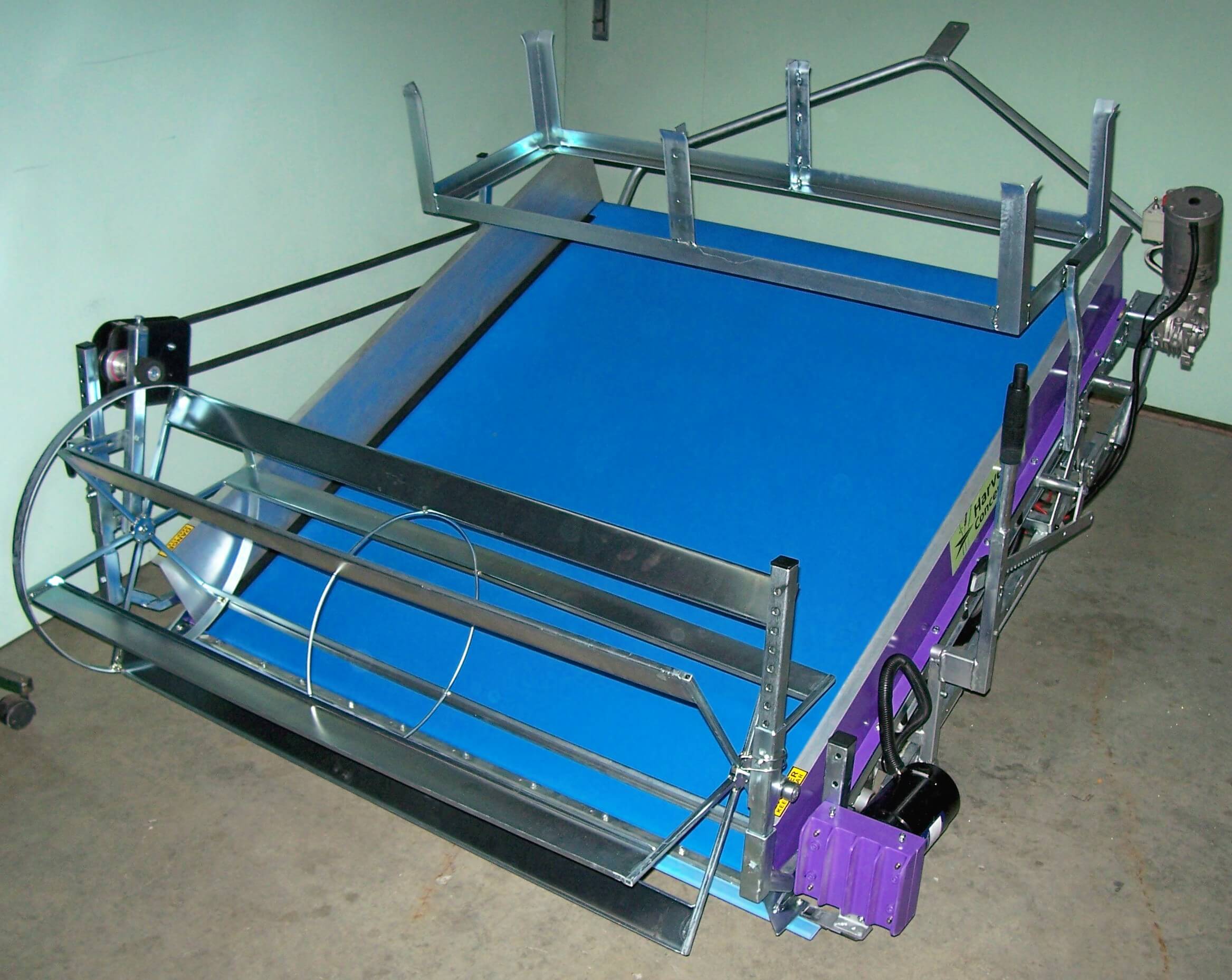

The HT-Shaver-BD (Bottom Drive) harvester is designed for harvesting flat bed, raised bed or field grown plants. The HT-Shaver-BD has a bottom drive gearbox for the cutter bar — nothing protrudes below the cutter bar. As the engine protrudes out one side of the harvester, the engine must be in a walkway or over the harvested area of the field. The gearbox is heavy duty and the engine is a Honda 4-stroke GX25.

With the collection bins removed and the cutter head raised it will clear uncut crops allowing easy manoeuvring of the harvester.

This is a serious harvester capable of harvesting more than 6 tonne of salad type crops per week! Typical crops the HT-Shaver-BD harvest include loose leaf salad plants and low growing herbs such as thyme, Rocket, Arugula, Baby Spinach, Baby Greens, Cress, Endive, Mache, Mizuna, Mesculin, Romaine, Spinach, Tatsoi, Baby Beet, Mache, Chicory, Micro Greens and others.

Also available as a self propelled model, and / or with 24v DC power to drive the cutter bar and belt (plus wheels in the case of the self propelled model). Click on the ‘Options’ tab for more detail.

- Adjustable cutter height from ground level up to 80 mm

- Engine driven industrial grade conveyor belt only drives when the engine is revved up

- Heavy-duty, low maintenance drive line

- 4-stroke Honda GX 25 engine

- Holds 2 recrate 75 vege bins

- Light weight frame zinc plated for durability

- Easily used by one operator who can walk behind the harvester or offset in a wheel track

- Cutting action controlled from operator’s position

- Cutting height (above bed): 10 mm (effectively ground level) to 80 mm

- Cutting width: 1200 mm

- Wheel track: 1415 mm centre lines

- Wheel drive: none

- Belt speed: 19.5 m/min max

- Weight, dry: 42 kg

- Collecting bin / bag: recrate 45 or 75

- Engine: Honda GX 25 4-stroke using unleaded gasoline

Dimensions:

| Width (mm) | Length (mm) | Height (mm) | cu.m (approx.) | kg (approx.) | |

|---|---|---|---|---|---|

| Ready to Use | 1600 | 2330 | – | – | – |

| For Freighting (on Pallet) | 1650 | 1750 | 850 | 2.4 | 80 |

Note: Specifications are subject to change without notice. Harvester Solutions implements a continuous product improvement program.

The base price is for the HT – Shaver – BD model with petrol engine driven cutterbar and framing to hold 2 recrate 75 vege bins.

36v DC self-propelled option (cutterbar still engine driven) HT – Shaver – SP

Refer to the handbook for routine maintenance.

Parts lists are also available in PDF format. Please contact us by using the form below and we’ll email you the PDF. If you are not sure which model you have, please state this when enquiring about parts and we will confirm from our records.

When placing a parts order, please quote the parts list drawing title, item number required and quantities.

Preventative Maintenance

You will become reliant on the harvester to do its job and if a breakdown was to occur you could find yourself in an awkward predicament. We recommend regular maintenance to help avoid breakdowns.

As well as the maintenance in the hand book we recommend at least annually, for regular users, stripping the reciprocating gearbox at the end of the cutter bar. Regardless of condition, replace all bearings and the two drive links which also hold bearings. Preload the housing with some grease but not full or it can hydraulic and jam the drive.

You can download the following documents:

● Handbook HT Shaver BD (688 KB)

Get In Touch

We design, develop, test and manufacture harvesters for all industries from low height crops, medium height crops to bush type and specialty styled crops. If you are in need of a harvester contact us to see how we can help you.

Phone Number

Email Address

Address

(Appointment Only)

Contact Us

Please use our contact form below to get in touch or email us.

Visits are by appointment only.